Everwide newsletter No.457

- skill484

- Jul 21, 2025

- 3 min read

Experiment § VHX-1000 Digital Microscope

To continuously improve our product development efficiency and quality control capabilities, we have upgraded our digital microscope from the VHX-200 to the next-generation VHX-1000 image analysis system (Figure 1). The new system supports magnification levels ranging from 100× to 1000× and features an RGB filter switching function. It allows users to adjust the wavelength bands based on the sample's material and observation needs, enhancing image clarity and contrast, and improving interpretation accuracy under microscopic observation (Figures 2,3). The VHX-1000 is equipped with a vertically adjustable Z-axis stage, enabling precise focus at various sample heights for layer-by-layer inspection. For example, in the case of a PCB workpiece, the microscope can stack multiple images to generate a 3D reconstruction. The measured thickness from this method was 1.541 mm (Figure 4), compared with 1.522 mm obtained using a micrometer, showing only a 1% deviation (Figure 5). With its exceptional measurement precision, the VHX-1000 will be an invaluable tool in our research and observation efforts. — By Mr. Wen-Hao Tsai

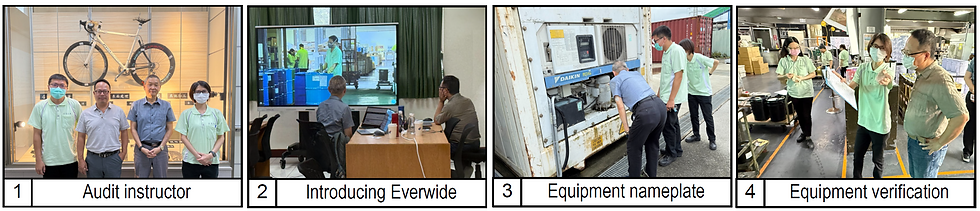

Activity § Third-Party Verification of Greenhouse Gas Emissions

This year, Everwide completed its third-party verification of greenhouse gas (GHG) emissions inventory once again. The scope of the inventory covers the entire plant, including electricity usage, equipment, air compressors, refrigerants, fire extinguishers, as well as employee commuting and waste management. The Environmental, Safety, and Health (ESH) implementation team led the inventory process to identify various indirect emission sources within the organization. The total emissions for 2024 amounted to 2,936.6 metric tons of CO2 equivalent (CO2e), with over 97% being indirect emissions primarily from raw material production, purchased electricity, and commuting activities. Our inventory was conducted following the ISO 14064-1:2018 standard and was verified by an external third party. Reasonable assurance was applied to Scope 1 (direct emissions) and Scope 2 (purchased electricity) to ensure data accuracy and reliability. We invite you to join us in doing your part to reduce carbon emissions within the scope of your ability (Figures 1–4).

Knowledge § What is static fatigue?(2)

In polymer fatigue testing, thermosetting plastics are generally more resistant to crack initiation, but once a crack forms, it tends to grow rapidly, leading to sudden material failure. Thermoplastics, on the other hand, are more prone to crack initiation, yet the crack propagation rate is relatively slow. The boundary between slow, long-term static fatigue under low stress and rapid failure under short-term high stress is often ambiguous, as the underlying fracture mechanisms can be quite similar. To improve fatigue life, the same strategies used for toughening or reinforcing polymers can be applied. Increasing the energy required for crack growth directly enhances fatigue resistance. For example, incorporating rubber particles or fibers into the polymer matrix can significantly increase its fatigue durability.

Living § Reflections on the R&D Meeting

Every year, our company hosts a year-end meeting—something I had never experienced at my previous workplaces. In the past, such meetings were usually limited to management-level presentations, focused on financial reports, sales figures, product development, and future vision. Regular employees were rarely included. At Everwide, however, all employees are invited to participate. The company openly shares its current status, the challenges it has overcome, and the direction for future development. During the meeting, team members from various departments give presentations that are clearly well-prepared and thoughtfully delivered. These reports effectively highlight each department’s key achievements over the past year, such as process improvements, environmental enhancements, equipment upgrades, major clients, and core products. It gave us a better understanding of how each department operates and allowed us to appreciate what we collectively accomplished in 2024. Beyond the professional content, there were also moments of relaxation and sharing. Our first boss’s extraordinary adventure to Antarctica, our second boss’s heartfelt support for local farmers, and our third boss’s amusing story of staying behind at the factory during the year-end banquet—all brought smiles to our faces. One part that left the deepest impression on me was the annual movie screening. Each year, a film with a meaningful theme is selected to spark reflections on values we may not often consider. These moments are always insightful and thought-provoking. I’m truly grateful that the company organizes such a meaningful and heartwarming year-end event. It allows us to recognize each other’s hard work and contributions, and better understand how a company moves forward with stability and purpose. I hope that in the future, we can continue to grow, create more value, develop more products, and realize even more possibilities. — By Ms. Yun-Ya Chuang

In Issue No. 457, Everwide upgrades its precision toolkit with the new VHX-1000 digital microscope, elevating imaging from 100× to 1000× and enabling 3D reconstructions via RGB filters and Z-axis focus stacking. The company also completed a comprehensive third-party audit of greenhouse gas emissions, reporting 2,936.6 metric tons CO₂e for 2024—mostly indirect emissions—verified under ISO 14064-1:2018 standards. Additionally, the newsletter explores static fatigue in plastics—highlighting how crack initiation and geometry impact material failure—and offers a heartfelt account from an R&D team member reflecting on Everwide’s inclusive year-end meeting that broadened employee insight and connection.

High Profile Bhopal Escorts