Everwide newsletter No.459

- skill484

- Aug 18, 2025

- 3 min read

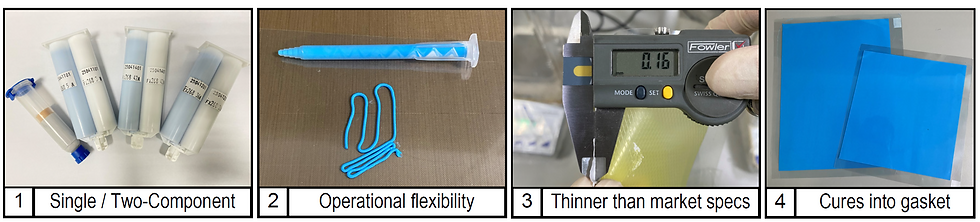

Experiment § Thermal Gap Filler

Thermal gap fillers are primarily used to fill gaps between electronic components, heat sinks, or other thermal management systems. With their excellent thermal conductivity, they efficiently transfer heat generated by the source to the heat-dissipating interface, thereby improving overall cooling efficiency and component stability. These materials are typically based on silicone or polyurethane matrices, loaded with high-conductivity fillers such as aluminum oxide (Al₂O₃), aluminum nitride (AlN), or boron nitride (BN) to enhance heat transfer performance. The FX268 series, developed by Eternal Materials, is a high-performance thermal gap filler (Fig. 1) formulated with a specially engineered silicone-based viscoelastic compound. It offers excellent flowability and gap-filling capability, allowing for flexible application on surfaces of various shapes and sizes (Fig. 2). Among them, the one-component FX268-80 features a thermal conductivity of 8 W/m·K and requires no mixing, simplifying the application process and improving production consistency. Additionally, the FX268 series can achieve a post-cure bond line thickness as thin as 0.16 mm (Fig. 3), surpassing the conventional minimum of ~0.5 mm for standard thermal pads (Fig. 4). This enables more efficient thermal designs, delivering a more reliable heat management solution for electronic devices. For more information about this product line, please don't hesitate to contact us. — Author: Mr. Huang, Yi-Hsun

Activity § Personnel Skills Assessment

To ensure that all employees operate by standard procedures, we have implemented a skills assessment and training system. New hires undergo a job-specific skills evaluation upon joining the company, while existing employees receive refresher training and re-evaluation every three years to maintain operational proficiency and consistency. When process updates occur or new equipment is introduced, relevant training and performance verification are conducted to prevent issues such as “inability to operate” or “incorrect operation.” By continuously optimizing our training program, we ensure that employees’ skills keep pace with evolving requirements, enabling us to deliver more stable and high-quality products and services to our customers.

Knowledge § Knowledge About Impact Strength (2)

In addition to the Izod impact test, several other methods are used to measure impact strength, including the Charpy, tensile impact, and falling weight tests. Each testing method is conducted at different loading rates, which can influence the measured impact strength. Some materials exhibit high toughness under slow tensile loading, yet behave in a brittle manner when subjected to high-strain-rate impacts. Different testing methods also involve other components of energy dissipation. For example: the energy lost by the pendulum after striking the specimen, the energy absorbed by specimen deformation and fracture, and the energy required to accelerate the specimen from rest to a velocity equivalent to that of the pendulum. Even with the same testing method, different materials may distribute the absorbed energy differently among these components. As a result, impact strength values should be treated as reference data only, and cross-material comparisons must be made with caution.

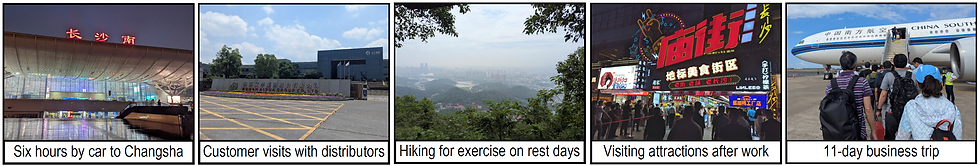

Living § Business Trip Experience Sharing

In May, I made my first business trip to China, entering through Shanghai and departing from Shenzhen, over a total of 11 days. Initially, I had little knowledge of the local market and culture, but by visiting several customers and distributors in person, I gained valuable experience. Our company offers a wide variety of products, but some of our distributor partners are not very familiar with them and are therefore unsure about how to effectively promote them. This made me realize that having good products is not enough—we also need systematic organization and clear explanations of each product’s strengths so customers can fully understand their value. During my interactions with distributors, I found that personal relationships are crucial. Meetings and presentations alone are far from sufficient; regular communication is needed to build trust over time. They also emphasized the importance of business ethics—if a customer already has a stable supplier, other vendors generally will not interfere. This trip also took me to more remote areas, where I visited factories to engage in technical exchanges with customers. Seeing us on-site made customers more enthusiastic, which will undoubtedly make future cooperation smoother. Despite a tight schedule, I still managed to take short hikes and enjoy local delicacies during the weekends, which became small but memorable highlights of the journey. This trip taught me that success depends not only on technology but also on effective communication, trust, and being always willing to go the extra mile. Success is never easy, but I will continue to work hard toward it. — Author: Ms. Lu, Chih-Yun

Comments